Artekk Panels – Fixing and Fabrication

The Artekk Large Porcelain Panel is a durable sintered material. It is suitable for various applications, including kitchen bench-top, splashback, flooring and wall tiles. Our marble-stone look tiles series is one of the most popular options for the bathroom tiles application. The larger tiles format will not only create fewer joints but also make a small bathroom look bigger, offering a uniquely uniformed finish.

Artekk Panel Sintered Porcelain structure and their many performance advantages allow their long-term use both externally and internally. A wide range of Fixing systems and processes are utilised for appropriately fixing Artekk panels across the array of their fit for purpose.

The appropriate mechanical and or mechanical fixing method for a given application must always be determined by the specific requirements of each project to ensure full compliance with related Australian Building Standards. Unique Design, Engineering , Environmental, Aesthetic and in place Panel performance will determine the right fixing system as specified by the responsible Architects and designers.

Following is a range of Artekk Panel fixing examples, ranging across internal, external, wall, floor are working surfaces applications and indicative guide of current practice in meeting related Australian Building Standards requirements for designer and installation reference.

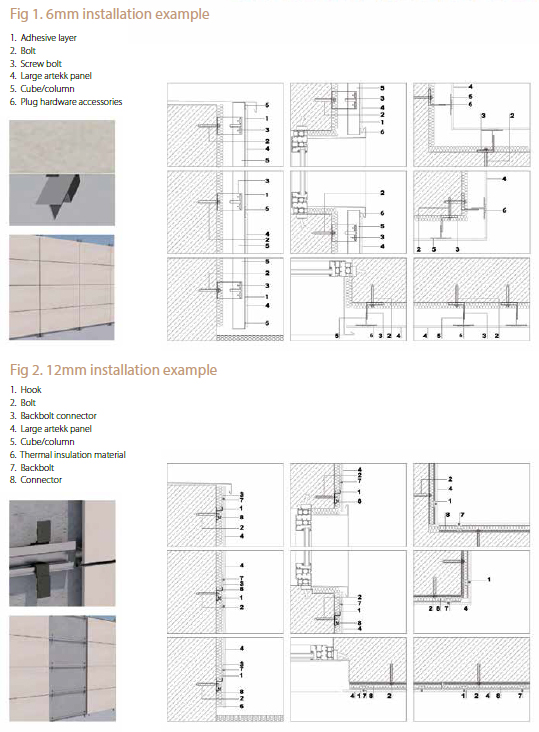

ARTEKK WALL FASCIA SYSTEM

Artekk panels are fixed using dry a hanging system to the exterior of buildings.

■ Extrusion profiles are available via Artekk on a range of load and substrate specification and produced in 6063T5 grade aluminium.

■ Stainless steel fixings and attachments are utilised in a spacing format to meet compliance with related Australian Building Standard specifications

■ Frame rails are fixed to the wall via mechanical and chemical fixing in compliance with related Australian Building Standards and as designed to suit the wall structural integrity.

Examples shown are reflecting 6mm & 12mm panel attachments (Ref Figures 1,2 & 3)

Adhering Artekk panels to solid substrates

Adhesion method using an optional mechanical safety fixing. Same method applies without safety fixing.

INTERNAL AND EXTERNAL APPLICATIONS

The laying system can be achieved by a full adhesion system with suitable adhesives. On 3200 x 1600mm panels, especially for exterior cladding where heights exceed minimum Council requirements, it is required that hidden mechanical safety fixings be used to allow the Artekk Panel wall installation in complete safety, more quickly whilst in compliance with good WPH&S practice. The mechanical fixing system, for Artekk Porcelain Panel is best installed at Artekk prior to site delivery.

Note for Clarity: All Artekk panel installation greater than a single 3200 x 1600mm height must include perimeter mechanical fixing (not chemical/adhesive fixing only) to ensure compliance with Australian Building Standards. Each project is unique,

and has its own fixing specification requirements which should be detailed in the Architectural /Design specification. Installers should consult the Architect or Building site supervisor before Artekk Panel installation if fixing detail is not clear, to ensure compliance with safety and Engineering process requirements.

Equipment required

■ Handling frame with suction cups

■ Suitable cement-based powder adhesive for full spread

■ 15mm round toothed trowel

■ 3 x 3mm square toothed trowel

■ Fixing tools to suit specified mechanical fixing/s (if required)

PREPARING WALL SUBSTRATE AND ADHERING ARTEKK PANELS

1. Ensure that the surface to be covered is solid, flat and free from dust.

2. Use a suitable adhesive (such as Laticrete or Mapei) for thorough spread and best adhesion, in accordance with Australian Building standards.

3. Spread the adhesive onto the surface to be covered (Ref fig 1) with a 15mm round toothed trowel across an area of 5/10cm more than dimensions of the Artekk panel.

4. With Artekk panel in a vertical position on the handling frame, spread adhesive onto the back of slab with a 3 x 3mm square toothed trowel – also wetting or buttering the Artekk panel thoroughly with adhesive.

5. Using the handling frame in a vertical position lay the Artekk panel up to the wall.

6. Before releasing the Artekk panel from handling frame, ensure necessary adhesion has been achieved he Artekk panel firmly in place.

7. To guarantee complete bonding of the Artekk panels and elimination of air, tap the Artekk panel from the middle towards the edges using a non-bounce 30-60 duro hardness plastic or rubber mallet.

8. Mechanical fixing - Before bonding the next Artekk panel, attach the hidden mechanical fixing (Ref fig 2) to the wall with the relevant

specified fastener/s. (If nails are used it is recommended to apply with a suitable gas powered device to a depth of not less than 27mm)

Health & safety process and equipment

RESPIRATORY PROTECTION

Always use proper protection, i.e., OSHA approved gloves and respirators.

CUTTING AND DRILLING

Always use wet methods of cutting and drilling to reduce generation of dust. The following Graph shows respective Silica Dioxide (Sio2) content from published accredited test data relating to the most commonly specified and used Natural stone, Ceramics, Engineered Stone composites.

Although the NATA approved laboratory testing of Artekk Porcelain products show that it has only a fraction of the Silica Dioxde content (less than 14%) of the other products listed, it is still necessary to avoid generation of dust at all times, and water cutting is the best means of achieving a dust suppressed safe operating environment.

SiO2 CONTENT

(Averaged from a range of published standard testing)

VENTILATION

Dust levels must be kept below recommended exposure level with proper equipment.

Do not inhale dust.PROTECTIVE GLOVES

Proper OSHA leather or cotton gloves.

EYE PROTECTION

Safety glasses with side shields or dust proof goggles.

OTHER PROTECTIVE CLOTHING OR EQUIPMENT

If special circumstances are required, then special equipment and clothing must be designed to meet the needs and requirements.

HYGIENIC PRACTICES

Wash exposed skin with soap and water after handling.